Plastic Injection Mould Maker26

Short Description:

JS MOULD Mold is professional plastic injection mould maker locate in south of China, we focus on making all the injection moulds that involving airoplane, medical devices parts,consumer electronic, office application, household application,industry,Commodity etc.we have been serving our customers…

JS MOULD Mold is professional plastic injection mould maker locate in south of China, we focus on making all the injection moulds that involving airoplane, medical devices parts,consumer electronic, office application, household application,industry,Commodity etc.we have been serving our customers from all over the world with 15 years experiences.

Five reasion to choose JS MOULD Mold to be Your Mold Building & Moulding Solution:

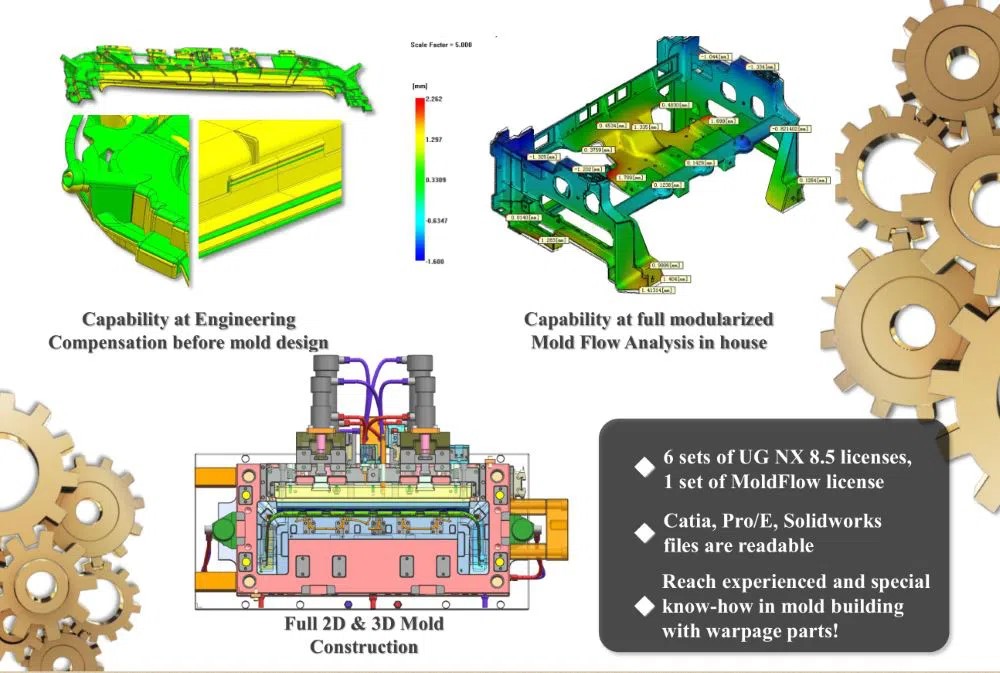

1. Professinal designers with more than 10 years

You know.“The long journey begins with the first step”. The quality mould construction begins with a sound designs.At JS MOULD we strive to design the molds that are robust in nature, with focusing on minimizing both in cycle time and easy maintenance.

2. Full control on time Delivery

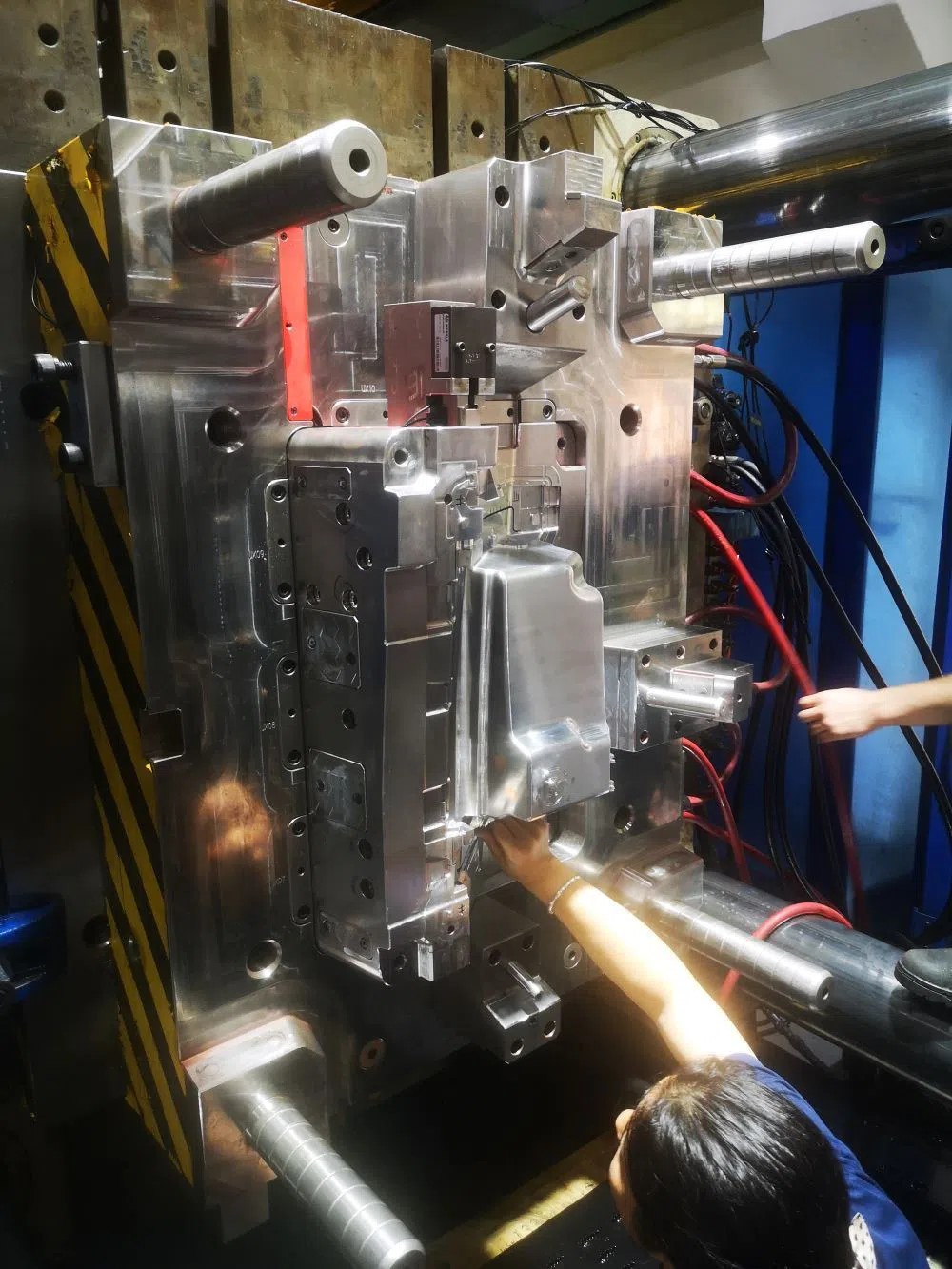

We have R&D centers located in our factory for setting, and sampling of injection molds., everything can be discussed while design then can reduce delivery time. Meantime will send weekly process report then can control delivery time easy, if meet problem during process will point out at first time, discuss & re-design on time that can make sure delivery time under control always.

3. Full control quanlity of building mould and moulding

JS MOULD mold is registered to ISO9001:2015 quality management standards, demonstrating our capability to consistently provide precision injection mold and plastic injected parts to meet and exceed customer and regular requirements.

With JS MOULD team mind of quality, and with a professional QA team who is directly report to boss, base on the through quality control system, and advanced and completed measuring equipment, quality insurance support from suppliers, and trust and encouragement on our quality from customers.

4. Establish a mold maintenance plan

after a set number of cycles have run on your production mold. We operate a first class tool shop with all the tools and equipment necessary to prevent and perform mold maintenance activities. We keep an accurate and digital history of any maintenance performed on an injection mold. We believe preventative mold maintenance is critical to the success of the mold.

5. Providing reliable one stop services.

we are also a responsible injection molding factory, injection machine from 45T to 1300T,in shot sizes from 1 to 80 ounces, all to tolerances of ±.001”.also provide pad printing ,Silkscreen,Spray painting, ultrasonic welding,Laser Etching and assembling to ensure you complete solution.